CEBIPRO

New analysis technologies for circular economy biorefineries

The project developed new high-tech analysis methods for characterizing new pulp grades and applications.

New analysis technologies in biorefineries

Innovative solutions for analyzing new pulp grades and process waters

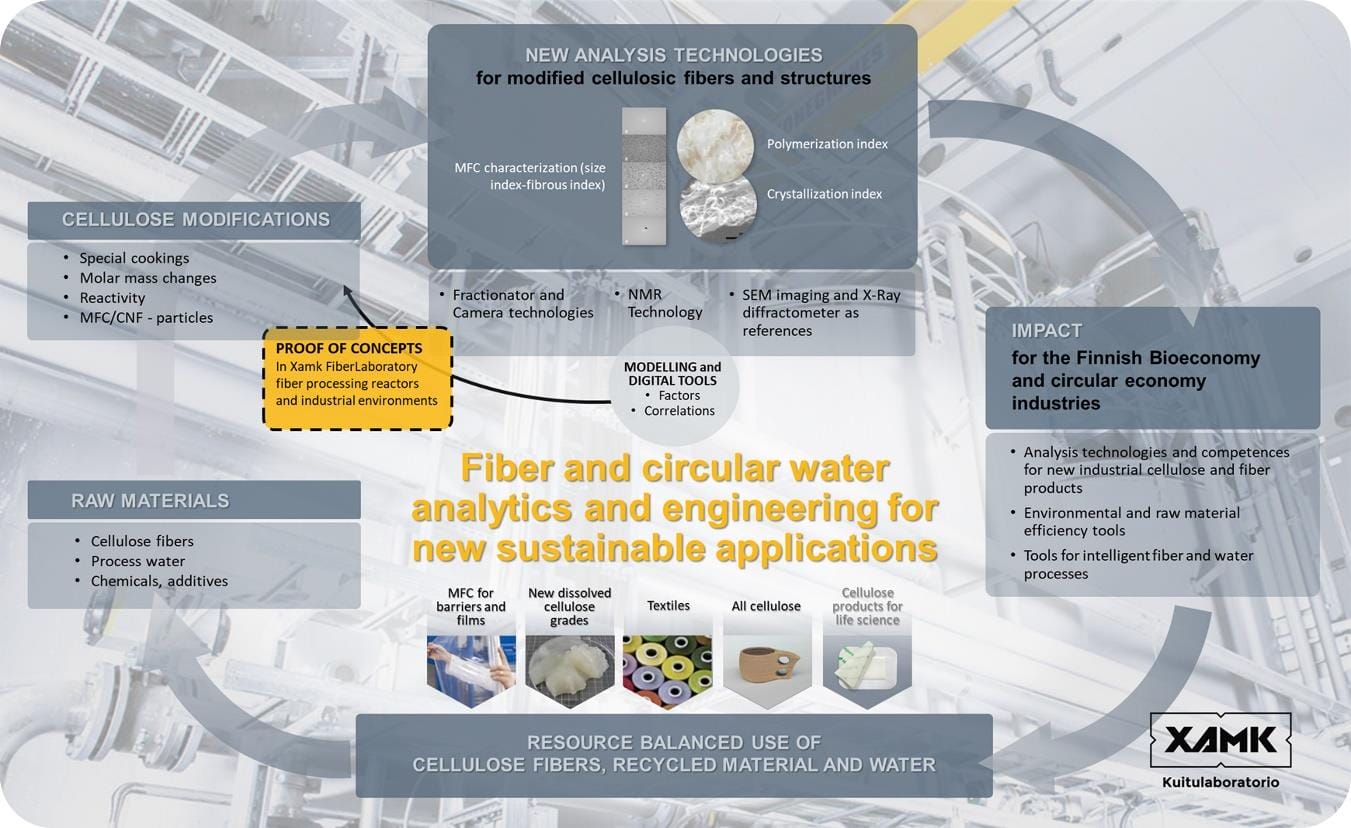

A wide range of new industrial applications for cellulose is being developed, including textiles, films, packaging, and other high-value products. The goal of the CEBIPRO project was to develop new expertise and solutions to support industrial applications and processes for new pulp grades.

Additionally, the project evaluated the suitability of new characterization techniques for online monitoring of chemical constituents in closed-loop water circuits and supported the development of process and wastewater technologies in biorefineries in collaboration with industry leaders and partners.

Advancing fiber and water analytics

In the CEBIPRO project, new high-tech analysis methods were developed for the characterization of novel celluloses and applications using fractionation and NMR techniques, and the suitability of these characterization techniques for monitoring process and wastewater in biorefineries was evaluated.

Key actions of the project

The key actions of the project were divided into the following work packages:

WP1. Structural fingerprinting – Fiber morphology

WP2. MFC characterization, flocs and retention

WP3. Polymerization index development

WP4. Modelling and simulations

WP5. Closed process water loops analytics

WP6. Proof of concepts and Piloting

WP7. Business case evaluation

WP8. Management, collaboration and dissemination

Results

The project’s most specific goals included the development of characterization techniques for the important degree of polymerization in cellulose modification, as well as the development of analysis methods that enhance environmental and water efficiency in processes.

A modeling approach was developed in the project to predict the strength properties of laboratory-produced sheets. However, applying the model under industrial process conditions still requires fine-tuning and repeatability tests. The project generated new expertise in the use of advanced analytical techniques, particularly in monitoring fiber refining, characterizing microfibrillated cellulose (MFC), and analyzing various fiber suspensions.

NMR methods were developed for both solid samples and process waters: the techniques for measuring crystallinity and degree of polymerization were accelerated, and continuous monitoring of organic load and suspended solids in process water was successfully demonstrated in a long-term pilot. The project resulted in a patent application, scientific publications, and a webinar, while international collaboration was strengthened, particularly with RISE in Sweden. Close cooperation with industry was essential and ensures the commercial applicability of the developed methods.

New knowledge, expertise, and collaboration

The CEBIPRO project at South-Eastern Finland University of Applied Sciences was part of the Valmet Beyond Circularity VETURI program. The program aims to develop process technologies, automation, and services by utilizing renewable and recycled materials, industrial side streams, and waste in collaboration with research institutions, universities, major industrial companies, and start-up companies.

Read more about the Valmet Beyond Circularity VETURI program.

The FiberLaboratory’s strengths lie in its profound expertise in NMR technology and strong fiber competence, which can be enhanced by utilizing a fiber analysis device based on UHD camera technology.

Experiences and articles

Integrated analysis of cellulose structure and properties using solid-state low-field H-NMR and photoacoustic spectroscopy

The study examines the structural details of cellulose by utilizing low-field proton nuclear magnetic resonance (H-NMR) to analyze the different types of hydrogen atoms in the cellulose molecule.

Xamk Forest, Environment and Energy Annual Publication 2024

The articles published within the project, “Uusien sellulaatujen jauhatuksen seuranta UHD-kamerateknologian ja NMR-analytiikan avulla” and “Measuring water retention value in microfibrillated cellulose”, have now been included in the 2024 annual publication of Xamk’s Forest, Environment, and Energy focus area.

Exploring the Molecular Structure and Treatment Dynamics of Cellulose Fibres with Photoacoustic and Reversed Double-Beam Spectroscopy

The study examined structural and chemical changes in cellulose fibers using an innovative analytical method. The article is the result of international collaboration within the project.

CEBIPRO at the FiberTech 2023 Forest Industry Days

The development prospects of measurement and analysis techniques improving the competitiveness of production lines and the management of specialty fibers (MFC, other specialty fibers) from the perspective of the CEBIPRO project, implemented by the Xamk Fiber Laboratory and part of the Valmet Beyond Circularity program.

Xamk Forest, Environment and Energy Annual Publication 2023

The introductory article about the project can be read in the 2023 annual publication of Xamk’s Forest, the Environment and Energy focus area, which features current research, development, and innovation projects.

“In the CEBIPRO project, fiber and water analysis techniques are being developed to characterize new pulp grades and applications.”

Facts

CEBIPRO – New analysis technologies for circular economy biorefinery processes

Info

Budget

Keywords

Contact

Project partners