Eastern Finland Wood Product Cluster (ITÄPUU)

The aim was to strengthen the cooperation and networking of wood industry operators to promote industrial wood construction in Eastern Finland.

New opportunities in the development of industrial wood construction

Diverse network of cooperation among wood product operators in eastern Finland as a key factor

Promoting industrial wood construction and raising the degree of wood processing as a priority

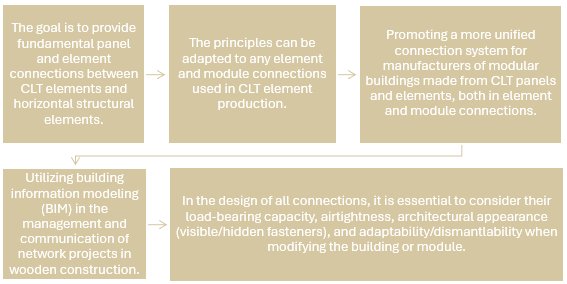

In Finland, the construction industry lacks standardisation of wood components and joints. Therefore, modelling is slow and tendering is difficult. The project promoted cooperation between wood construction industry actors across the country by developing, modelling and illustrating wood construction solutions to improve their standardisation. The Xamk sub-project focused on product development, testing and standardisation activation of jointing and structural solutions for wood-hybrid construction between RDI actors and SMEs.

ITÄPUU – Final Report: The Role of Xamk as a Sub-Implementer

The final report of the Itäpuu project, focusing on the role of Xamk as a sub-implementer, is available below. The report provides a comprehensive overview of the outputs produced and the results achieved through the measures implemented during the project.

Key actions of the project

WP 1. Eastern Finland wood product cluster network organising and cooperation

WP 2. Promoting industrial wood construction and raising the degree of wood processing

WP 3. Promoting export of industrial wood construction

WP 4. Communication, dissemination and exploitation

.

.

Events

ITÄPUU Project launched in the spirit of a company opening party

Xamk’s Industrial Wood Construction Laboratory’s company opening ceremony was held on Friday 24.5.2024 in Savonlinna, Finland. The event was attended by over a hundred experts and company representatives, and the weather was beautiful. The sun was shining from a clear sky all day, and at lunchtime the local vendace of Puruvesi with side dishes tasted great outside. The company presentations and demonstrations and the new research equipment in the laboratory generated a lot of enthusiasm and new discussions among the participants.

This festive atmosphere also helped to kick-start the Itäpuu project with a first meeting of project actors on site, which was attended by a large number of project actors. The main implementer of the project from Kuhmo and the co-implementers, the Measurement Unit of the University of Oulu in Kajaani, the Natural Resources Institute of Finland in Joensuu and Savonlinna and the South-Eastern Finland University of Applied Sciences in Savonlinna were present. Discussions and exchanges of ideas were actively taking place on the content and objectives of the project, while at the same time meeting companies and designers in the wood sector. As a result, the wood products cluster in Eastern Finland continues to move forward.

Trip to Kuhmo Woodpolis: business visits and a project workshop with ITÄPUU Project operators 27 – 28.8.2024

ITÄPUU Project operators gathered in Kuhmo Woodpolis on 27-28 August 2024. During these two days, the experts of the project visited companies in the wood products industry in the region, discussing aspects of operations, networking and further development, and organised the first project workshop, where they structured common objectives and measures through presentations of the work package contents prepared by the implementers.

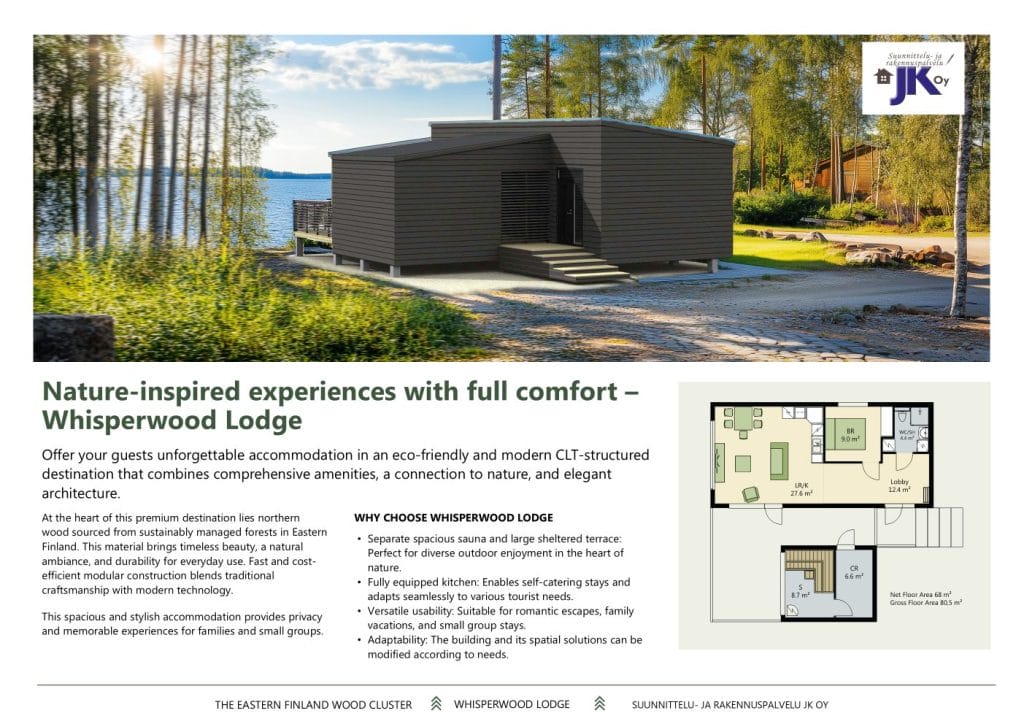

On the first day, company visits were carried out to Luottopuu, Oy Crosslam Kuhmo Ltd, Kuhmo AA-Puu Oy, and Oy Timber Frame Ltd. The company visits were also accompanied by Japanese and Nordic export experts from Masame Mokuzai Finland Oy, who have been proactive towards the ITÄPUU Project. During the visits, the companies’ activities were familiarised and trends in industrial timber construction were openly discussed. With the export experts, ideas were raised on export conceptualisation in relation to the company’s sales lines, where the company specialises in structural timber joinery products and small, mobile, and stationary residential and accommodation buildings. Finally, at a summary event of the visits, we heard the views of the local Design and construction service JK Oy on CLT module construction for detached houses, which could also be a boost for the latter export line.

The visits were successful, and the discussions were fruitful, even though the schedule was tight. Overall, the companies in the region have a strong network of cooperation and development, aiming to promote wood processing and business growth based on industrial wood construction. A good example of this during the company visit was the ProLog® CLT log product, which is a non-compressible log product that has been the result of innovation and development by Crosslam and Timber Frame in recent years, and which we were able to view and feel on site. At the end of the day, we visited the Lentua Hall in Kuhmo House, where a total of 60 kilometres of Kainuu timber is on display in the surface structures of the concert hall. These experiences were a good conclusion to the day of the visit.

On the second day, an intensive and effective 1st Project Workshop was held among the ITÄPUU Project operators, where they delved into the driving of common objectives and action lines, drawing on the competence profiles of the implementing organisations. Jointly prepared follow-up measures were written down, which will serve as a basis for the further development of the ITÄPUU Project in line to achieve its practical objectives.

Promotion of Joint and Structural Solutions in Timber-Hybrid Construction

The Eastern Finland Wood Product Cluster project focused on advancing industrial timber construction and increasing the degree of wood processing. The aim was to increase the use of wood in public and large-scale construction projects as a result of development work on timber structures.

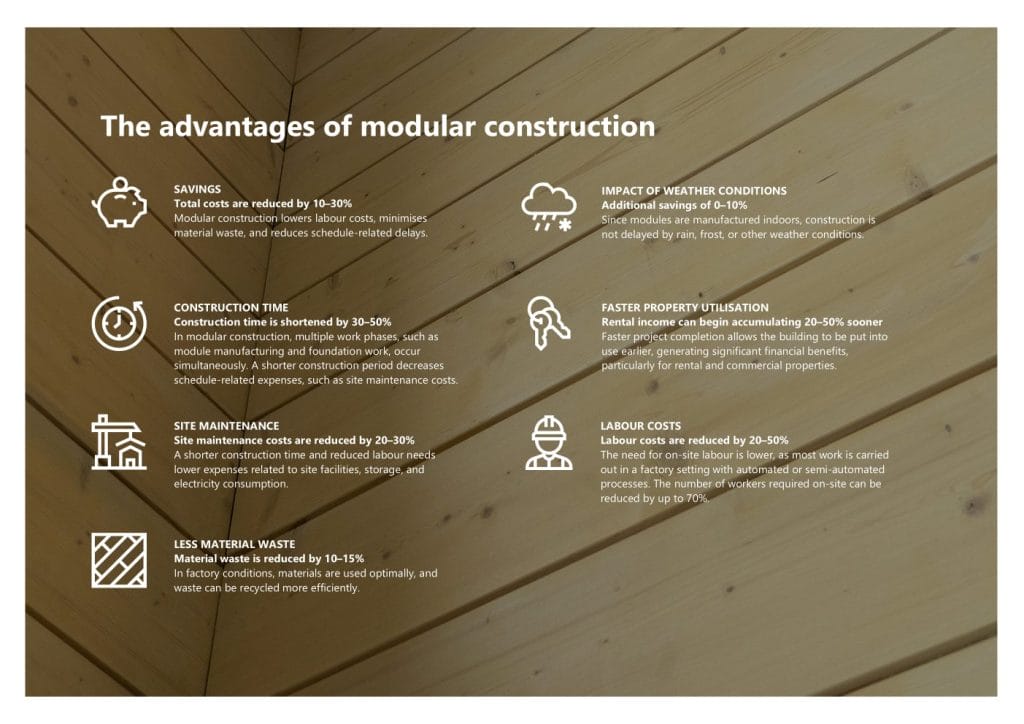

The project carried out innovative case studies on internationally competitive timber structural solutions from the Eastern Finland region. In addition, the project advanced design guidelines and the standardization of structures, joints, and elements for solutions of particular importance to Eastern Finland. Modular and standardized solutions were used to significantly improve the efficiency of timber construction, and they were also a prerequisite for the growth of timber construction exports. Through these measures, the project sought to improve, simplify, and clarify the usability, cost-effectiveness, and quality of timber construction solutions in large-scale building projects.

Several wood product industry companies participated in the development work, and through their cooperation, visual output material was produced for the developed solutions. For the case studies, Insinööritoimisto Lahtela Oy acted as the competitively tendered structural testing consultant, working in collaboration to define the research topics and testing plans.

Case Study Topics:

AIRBORNE SOUND INSULATION OF A CLT-STRUCTURED DOOR LEAF IN FLAT ENTRANCE DOOR IN APARTMENT BUILDINGS

DEVELOPMENT OF A RADIAL-SURFACED HYBRID PANEL

DEVELOPMENT OF A CLT LINTELN BEAM INTO ELEMENT OPENINGS

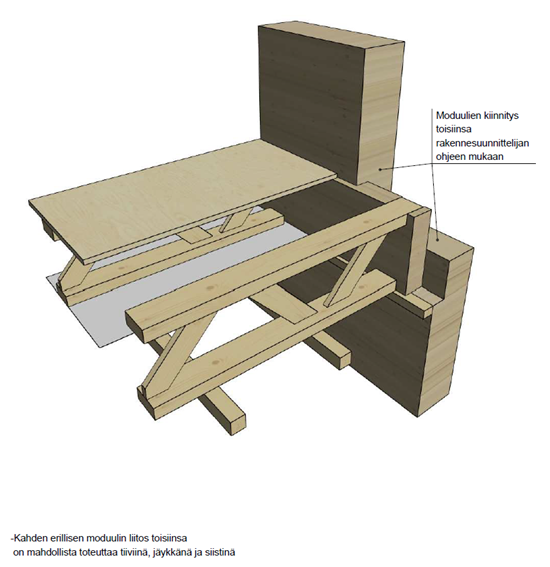

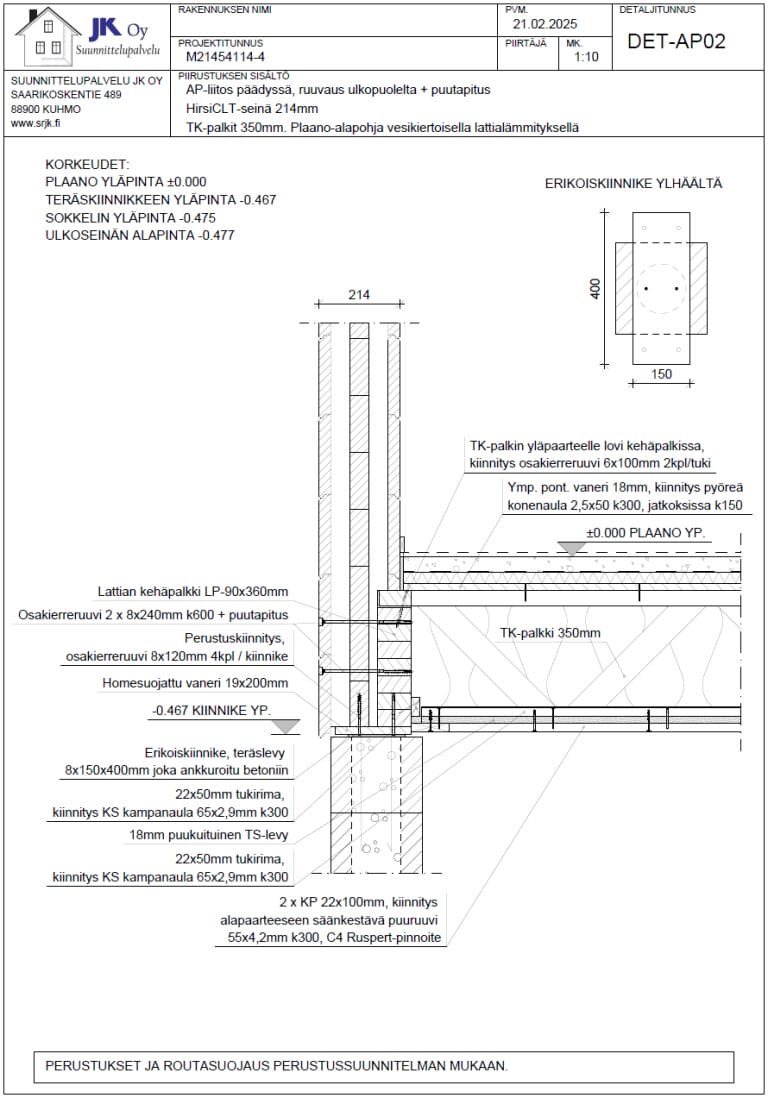

In addition to the case studies, the standardization of joint and structural solutions, as well as the promotion of exports, were enhanced through a flexible, modular CLT demo house concept. In this work, Suunnittelu- ja Rakennuspalvelu JK Oy acted as a key competitively tendered partner. The demo house concept resulted in technical drawings (permit drawings), conceptual 3D element joint and structural models to support the standardization of CLT modular construction, and a compiled report. Furthermore, joint marketing material was produced on the export concept and the cluster network, as well as on the strengths of the Eastern Finland region, to support both domestic and export promotion. The production of this material was carried out in cooperation with the competitively tendered marketing agency HaukiMedia Oy.

The communication events disseminated information on the project’s results, sites requiring special attention, new timber construction solutions, and concrete measures through which the establishment of the wood product cluster could be promoted.

Case studies

CASE STUDY 1:

AIRBORNE SOUND INSULATION OF A CLT-STRUCTURED DOOR LEAF IN FLAT ENTRANCE DOOR IN APARTMENT BUILDINGS

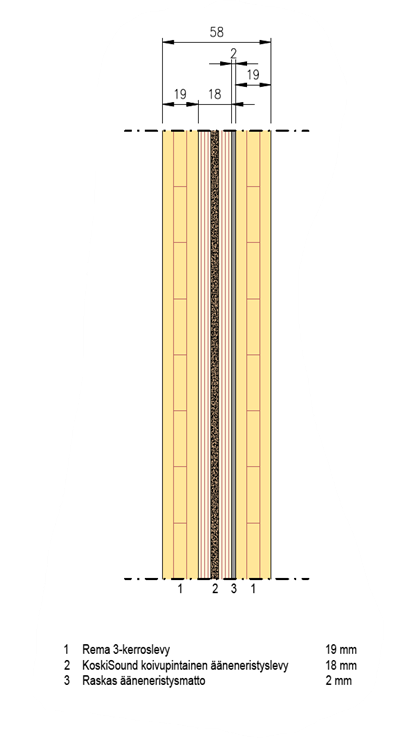

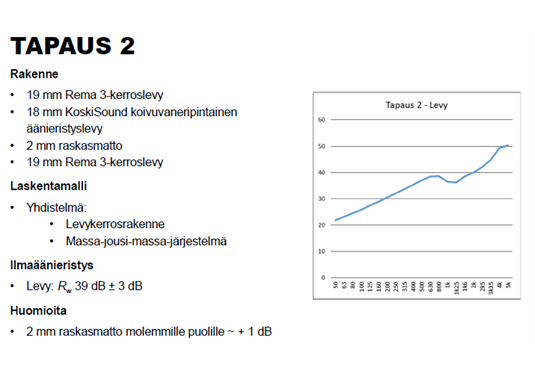

The project examined the airborne sound insulation performance of a CLT-structured door leaf, with the aim of determining under what structural conditions this type of door leaf could be used as an apartment entrance door. Such doors require a minimum standardized level difference of 39 dB (DnT,w), which can already be achieved through laboratory measurements or modeling methods with an airborne sound insulation value of 37 dB (Rw). In addition, the suitability of the structures for use as internal partition wall and inter-room door solutions was also assessed.

In the study, the airborne sound insulation of the CLT door leaf structure was investigated through computational analysis, from which usable results are now available. The calculations aimed to identify optimal and high-quality product development solutions in which correctly targeted building materials guide sustainable energy and material solutions. The analysis took into account the thickness of the structures as well as the cost-effective manufacturability and competitiveness of the products, which manufacturers can utilize in the product development of their own production.

The computational results show that increasing the mass of the door leaf provides only limited benefit if the layer intended to be flexible does not function as flexible in practice. Thus, a flexible layer appears to be a promising approach from an acoustic performance perspective. Many sound-insulating door leaves currently on the market indeed consist of panel layers combined with flexible layers.

In the calculations, in addition to the CLT structure, materials such as birch plywood–faced sound insulation board, heavy rubber matting, MDF, and fiber gypsum board were used in various combinations.

CASE STUDY 2:

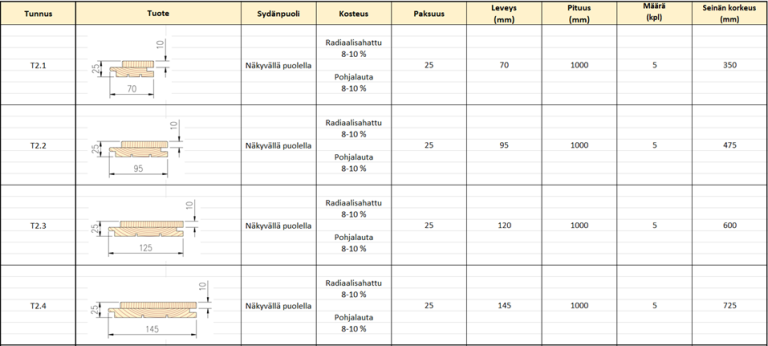

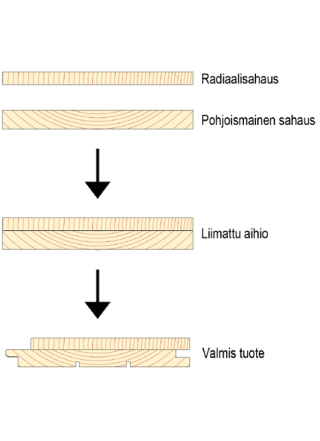

DEVELOPMENT OF A RADIAL-SURFACED HYBRID PANEL

The project investigated an innovative hybrid cladding panel produced by combining a thin radially sawn plank with a thin normal plank manufactured using Nordic sawing practices. The aim was to determine what benefits this product solution could offer compared to existing wooden cladding panels. The study mainly focused on deformations caused by moisture fluctuations.

Prototype designs of the hybrid panels were first developed, after which the panels were manufactured and subjected to preliminary moisture behavior testing. This made it possible to identify what kinds of deformations occurred in the panels due to changes in moisture (e.g. twisting, cupping, and bowing), and whether the panel solution exhibited significantly better weather resistance than existing alternatives. In addition, the manufacturability and cost competitiveness of the product solution were evaluated.

The results exceeded expectations, as no cracking or other defects appeared in the radially sawn surface boards of the hybrid panels, even though the prototypes were exposed to extremely severe moisture variations. Furthermore, the dimensional stability and appearance of the hybrid panels were excellent.

The research utilized the equipment and expertise of the industrial wood construction laboratory at Xamk in Savonlinna, along with the support of project partners.

CASE STUDY 3:

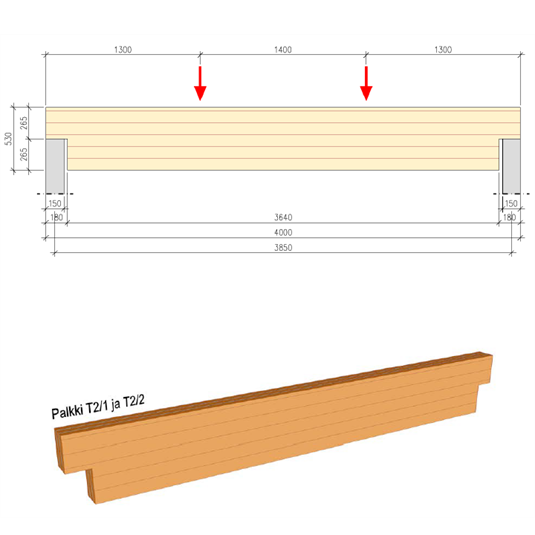

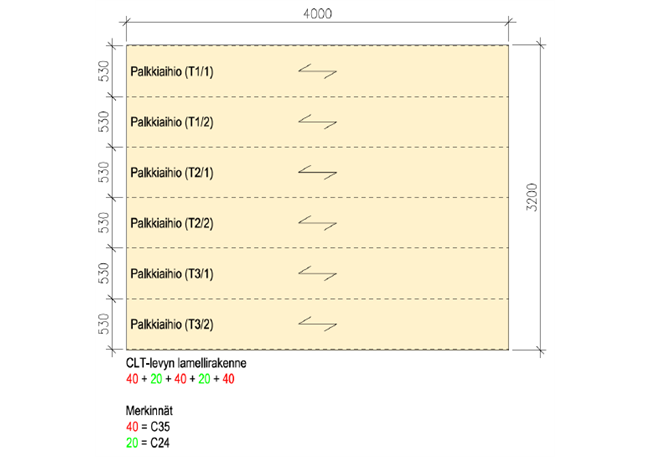

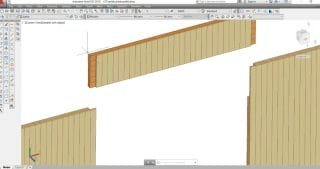

DEVELOPMENT OF A CLT LINTELN BEAM INTO ELEMENT OPENINGS

The project explored the development of a CLT (cross-laminated timber) lintel beam by utilizing stronger structural lumber grades. In CLT wall elements, the beams spanning openings often become the limiting factor, requiring replacement with alternative beam solutions such as glued laminated timber (glulam). However, this is not always an ideal solution from either a structural or visual standpoint. The study aimed to determine whether significantly higher load-bearing capacity could be achieved by using higher lamella strength grades—specifically C35 sawn timber—in a structure where CLT panel lamellas are currently manufactured exclusively from C24 grade timber.

The manufacturing concept for the CLT beam solution was designed so that the longitudinal lamellas were larger in dimensions and strength, as these carry the applied loads, while the intermediate lamellas were responsible for the dimensional stability of the structure. At the time of project implementation, there were no unified Eurocode design rules for holes or notches in CLT beams; however, the beam capacity could still be theoretically calculated and additionally verified through testing, yielding usable result values for the CLT beam. In the preliminary test, notched and perforated beams were loaded and compared with a solid beam.

From the perspective of bending and shear resistance, the CLT test beams proved to be significantly stronger in the load tests than predicted by the calculations. This was partly explained by the fact that in the test beams, the span-direction lamellas were of strength class C35, while the transverse lamellas were of strength class C24. In the calculations, all lamellas in the beam cross-section were assumed to be of strength class C24. From the deflection perspective, however, the results were surprising: the deflections of the CLT test beams were 34–40% greater than those predicted by the calculations. The deflections should have been smaller than calculated, since the test beams used a combination of C35 and C24 lamellas, whereas the calculations assumed all lamellas to be C24. This issue warrants further investigation.

The load tests and the testing report were carried out at Xamk’s Industrial Timber Construction Laboratory in Savonlinna.

Standardization of Joint and Structural Solutions & Promotion of Export

Modular CLT Demonstration House with Accommodation Solutions

The project aimed to advance the development, competitiveness, and implementation of industrial wood construction by leveraging the expertise of the Eastern Finland wood product cluster. It has produced materials on the development of joint methods, modularity, and conceptualization in CLT products, contributing to the standardization of the industry.

Creation of Domestic and Export Marketing Materials

The key objective was to align the expertise of Eastern Finland with customer needs both domestically and in exports. To achieve this, a professionally designed visual marketing package was created to capture customer interest in the region, its products, and companies.

The marketing material consists of three main parts:

- General introduction to Eastern Finland and the project stakeholders’ areas of responsibility

- DEMO product family, including architectural-level materials on CLT demonstration house modules

- Cluster company presentations

The complete material package enhances the recognition, appeal, and commercial potential of industrial wood construction, related building components/modules, and the companies involved.

More information

Facts

Itäpuu – Eastern Finland wood product cluster

Info

Budget

Eastern Finland Wood Product Cluster project is co-funded by the European Union, granted by the Regional Council of Kainuu. Xamk’s part of the total budget is € 149 728 €, from which the amount of EU funding is € 119 782.

The City of Savonlinna is committed to long-term funding of development projects related to wood construction by Xamk and LUKE. However, the project funding decision is still pending. City of Savonlinna’s share of municipal funding: € 14 973

Keywords

Project partners