FiberLaboratory

FiberLaboratory promotes the sustainable development of the forest and technology industry as well as the sensible use of resources. We support the competitiveness of businesses by developing technology that saves energy and water and reduces carbon dioxide emissions.

We develop technologies for Fibre products of tomorrow.

The FiberLaboratory offers an extensive range of research and development services to industry

We develop solutions that save water and energy, pilot new methods for treating water and sludge, and promote the further processing of wood fibre.

We are an innovative, networked operating environment for developing future bioproduct processes, implementing new ideas, solving process technology problems and testing industrial maintenance.

The research unit also includes Industrial Wood Construction and Technical Testing Laboratory in Savonlinna.

Xamk Industrial Wood Construction Laboratory is part of the FiberLaboratory

.

Services

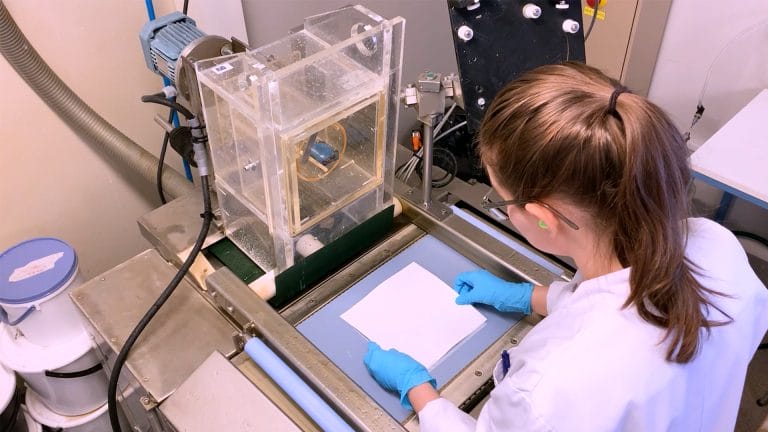

We are specialised in phenomenon and pilot-scale research — both needed to create new high-tech solutions. Services can be selected from rental premises to full-service test-run packages.

Industrial technology development of forest biorefinery processes

Industrial technology development of forest biorefinery processes

Large-scale processes and comprehensive technology mapping.

Practical testing

Practical testing

Services can be selected from rental premises to full-service test-run packages.

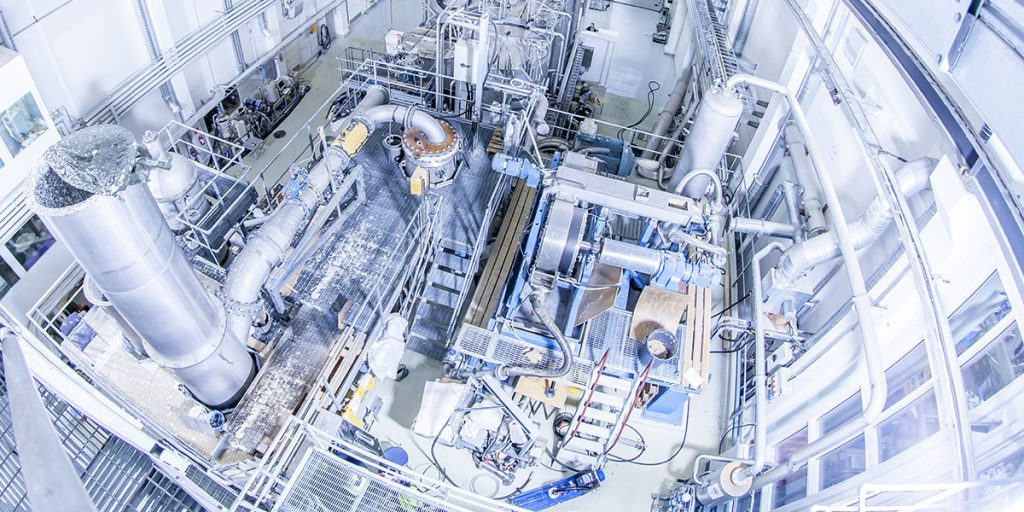

Piloting

Piloting

We offer an extensive range of services that are tailored to customer requirements.

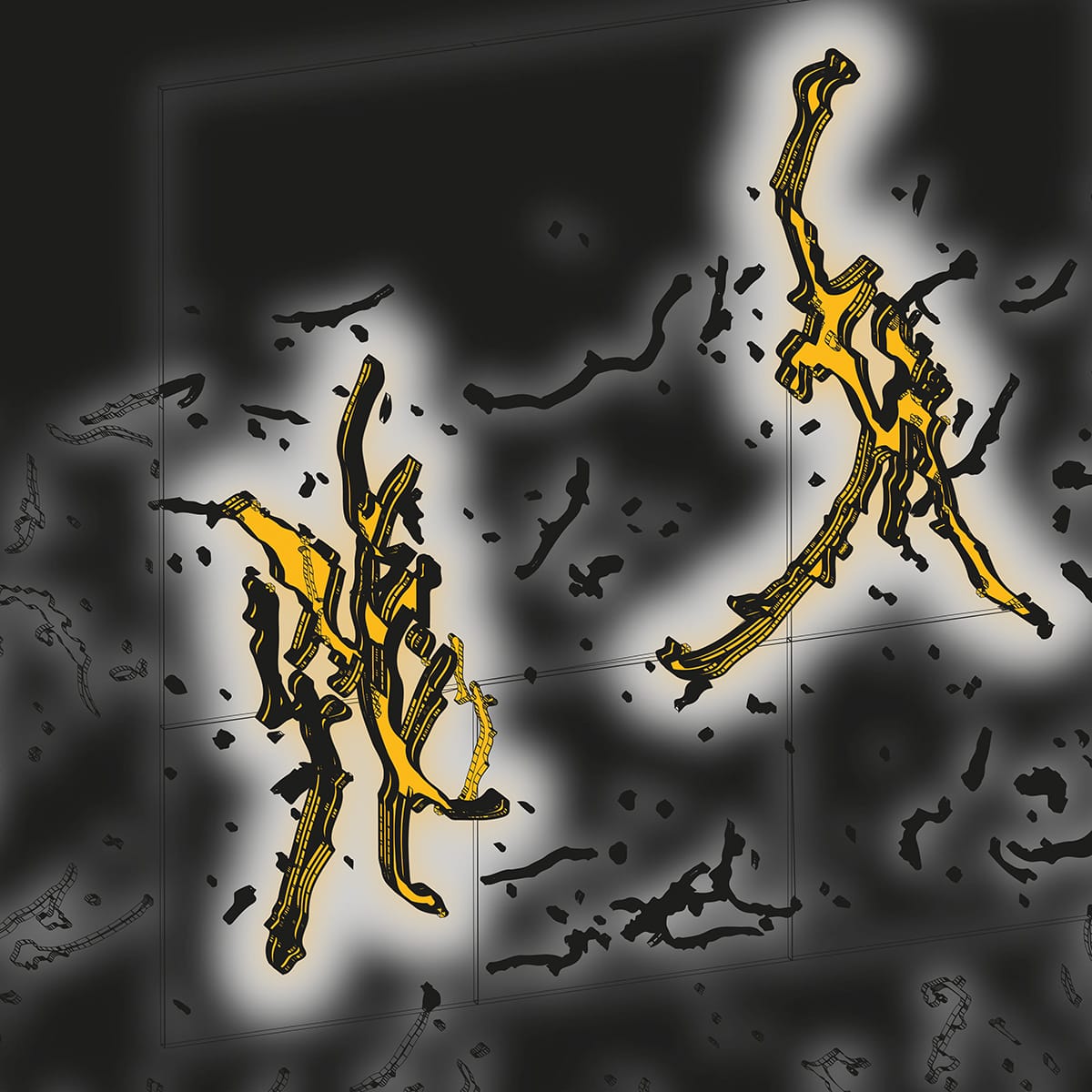

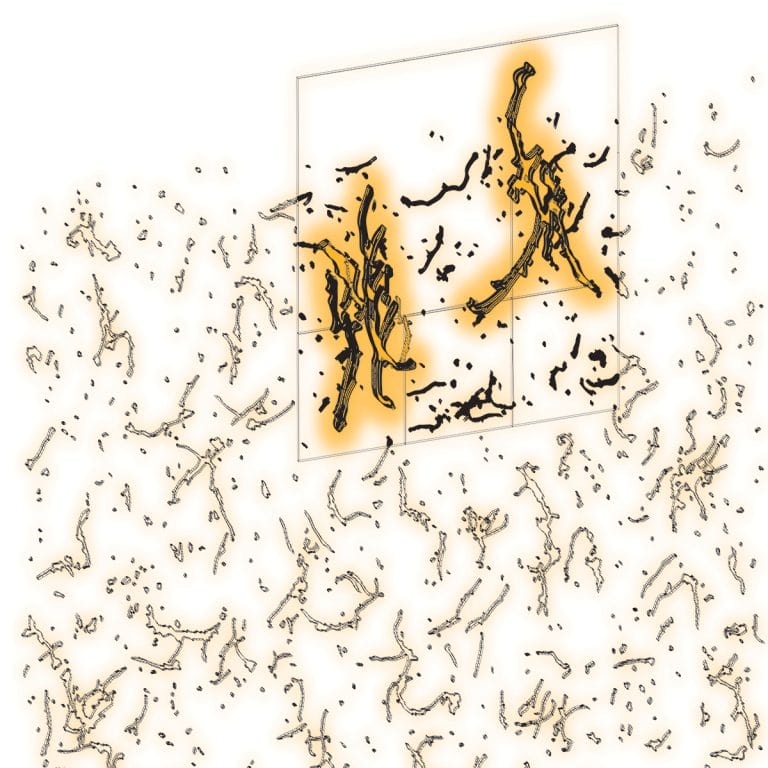

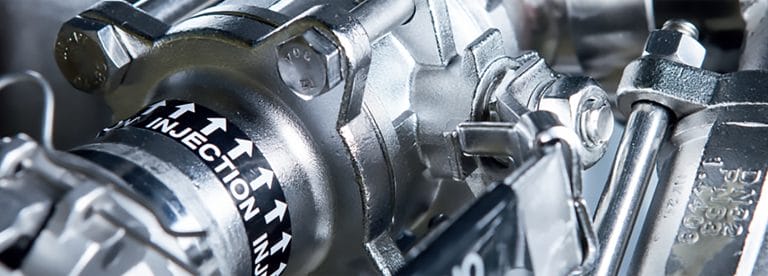

Research into rapid mixing phenomena

Research into rapid mixing phenomena

Serves to enhance industrial processes.

Development of microcrystalline cellulose production and applications

Development of microcrystalline cellulose production and applications

The raw material of microcrystalline cellulose is wood fibre. There are a lot of potential use cases.

Research services

Research services

The results and new solutions support the competitiveness of the companies.

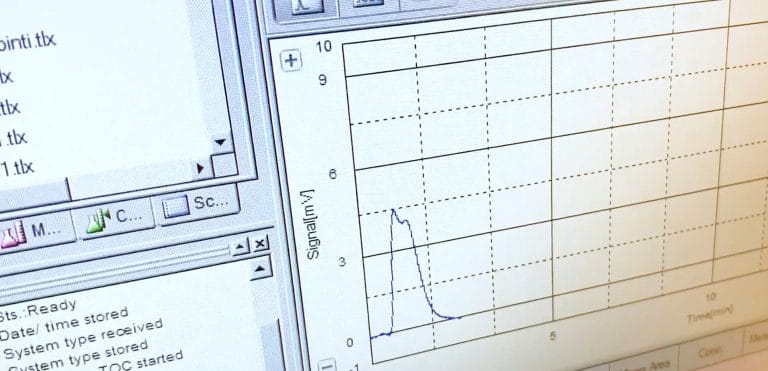

Laboratory analysis services

Laboratory analysis services

We report the results and suggestions of improvements, taking into account the cost-efficiency of the process.

Solutions for a variety of needs – How can we help you?

We offer an extensive range of services that are tailored to customer requirements. We conduct comprehensive technological mapping for customers. This may take place at a customer’s factory in which we inspect the operations of process equipment and have samples taken for laboratory analysis.

We report the results and suggestions of improvements, taking into account the cost-efficiency of the process. Services can be selected from rental premises to full-service test-run packages.

.

Environmentally friendly method for capturing and storing carbon dioxide

Phenomenon and pilot-scale research

Research and development

Engineering education

.

In our cooperation network we have about 100 companies from all over Finland.

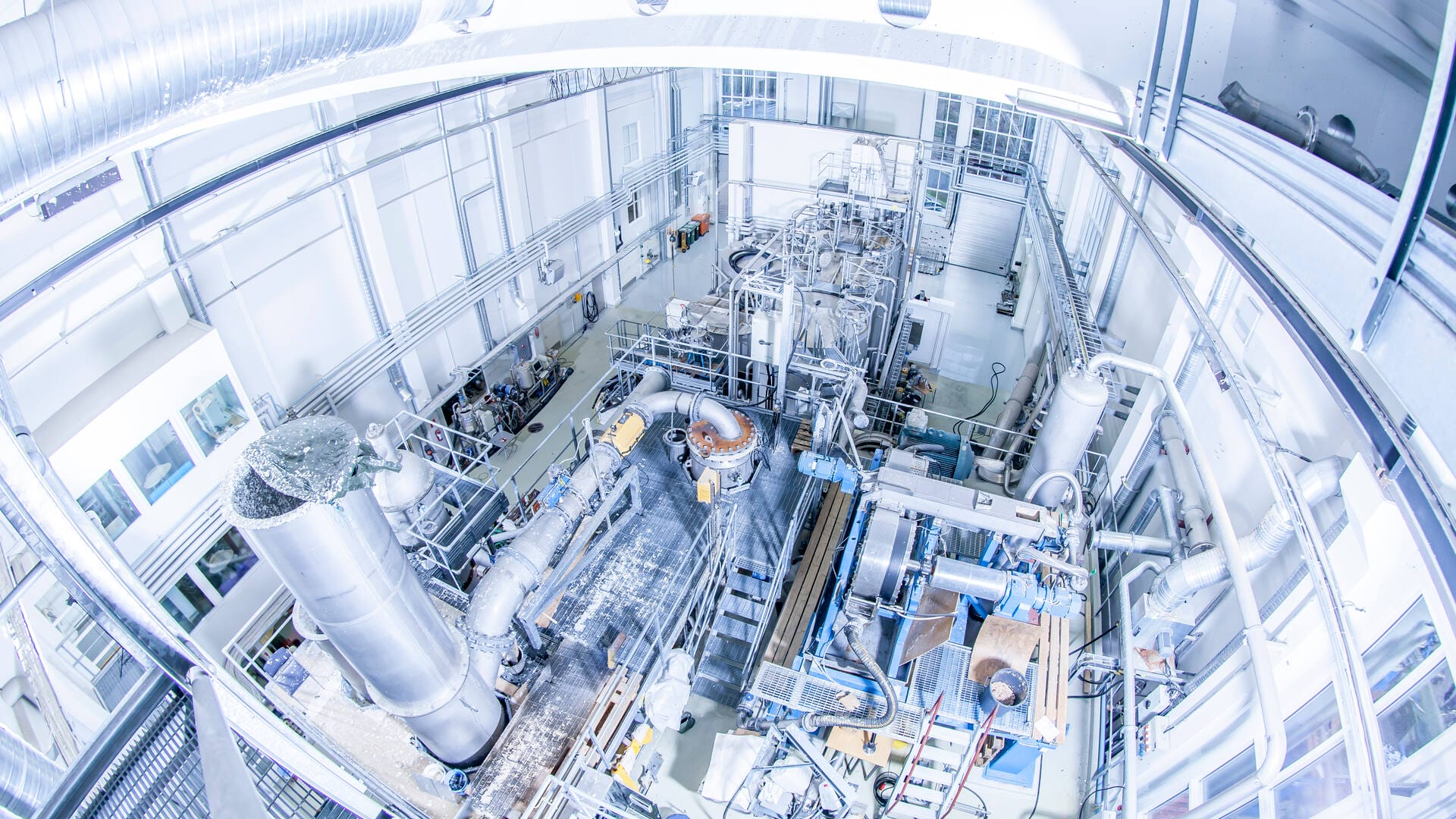

The FiberLaboratory has fiber, water and wastewater laboratories, piloting equipment up to industrial scale and portable piloting equipment for factory tests. The total floor area of the FiberLaboratory is now approximately 1600 m2. From that area fiber, water and wastewater laboratories takes approximately 160 m2 and the piloting facilities have a total floor area of approximately 680 m2.

The FiberLaboratory belongs to Forest, the Environment and Energy focus area of South-Eastern Finland University of Applies Sciences.

Among research centres the most important are:

VTT Technical Research Centre of Finland Ltd

Natural Resources Institute Finland Luke

Aalto University

"Productive collaboration since 2005

RDI Projects

Sustainable packaging solutions of the bio-circular economy

CEBIPRO – New analysis technologies for circular economy biorefinery processes

UMaMi – New modeling, measurement and process concepts to improve the production, raw material, energy and environmental efficiency of the bioproduct mill

NextGenMix – Novel Mixing Technologies and Future Bioproduct Manufacturing

Noheva – Forest Bio Technology Park Green Grow Up

.

Location

FiberLaboratory and Industrial Wood Construction Laboratory are situated next to each other in Technology Park Noheva in Savonlinna.

Address:

South-Eastern Finland University of Applied Sciences

FiberLaboratory

Vipusenkatu 10, FI-57200 Savonlinna

FINLAND

Frequently asked questions (FAQ)

The FiberLaboratory is an innovative, networked operating environment for developing future bioproduct processes, implementing new ideas, solving process technology problems and testing industrial maintenance.

We have over 15 years experience of pulp and board mill processes, especially under topic of mixing technologies and processes in different consistencies, imaging and camera technologies for the process research and analytical services.

We constantly collect development needs and ideas from our stakeholders. We help in the development efforts of ideas, and we are looking for funding to implement projects. We make bold and proactive project openings that meet the needs of growth-oriented companies, the public sector and the region in the long term, and we aim for concrete results that will be used by the companies in the region. We always create something new and useful: we find solutions and develop good ideas into practice. Contact us and tell about your project idea!

Contact us!

The Savonlinna FiberLaboratory began operating in 2005. At that stage, a pulp and environmental technology research group from Mikkeli University of Applied Sciences, nowadays South-Eastern Finland University of Applied Sciences, was working in the regional paper technology unit of the Lappeenranta University of Technology. In 2011, the FiberLaboratory was transferred to University of Applied Sciences in its entirety.

Since the beginning, the FiberLaboratory has offered testing and analysis services for suppliers of equipment and chemicals in the sector, and for the forestry industry. It has also accumulated expertise in the area as a result of its research projects.

Today, the laboratory’s services also cover water and sludge research. Doctoral theses and patents demonstrate the laboratory’s international expertise. The FiberLaboratory’s activities have also expanded into education in bioproduct technology, which creates expertise for future bioproduct processes.

We invite you to contact us.