INNOMIN

Environmental efficiency for mineral processing through the innovation network

Environmental efficiency for mineral processing through the innovation network

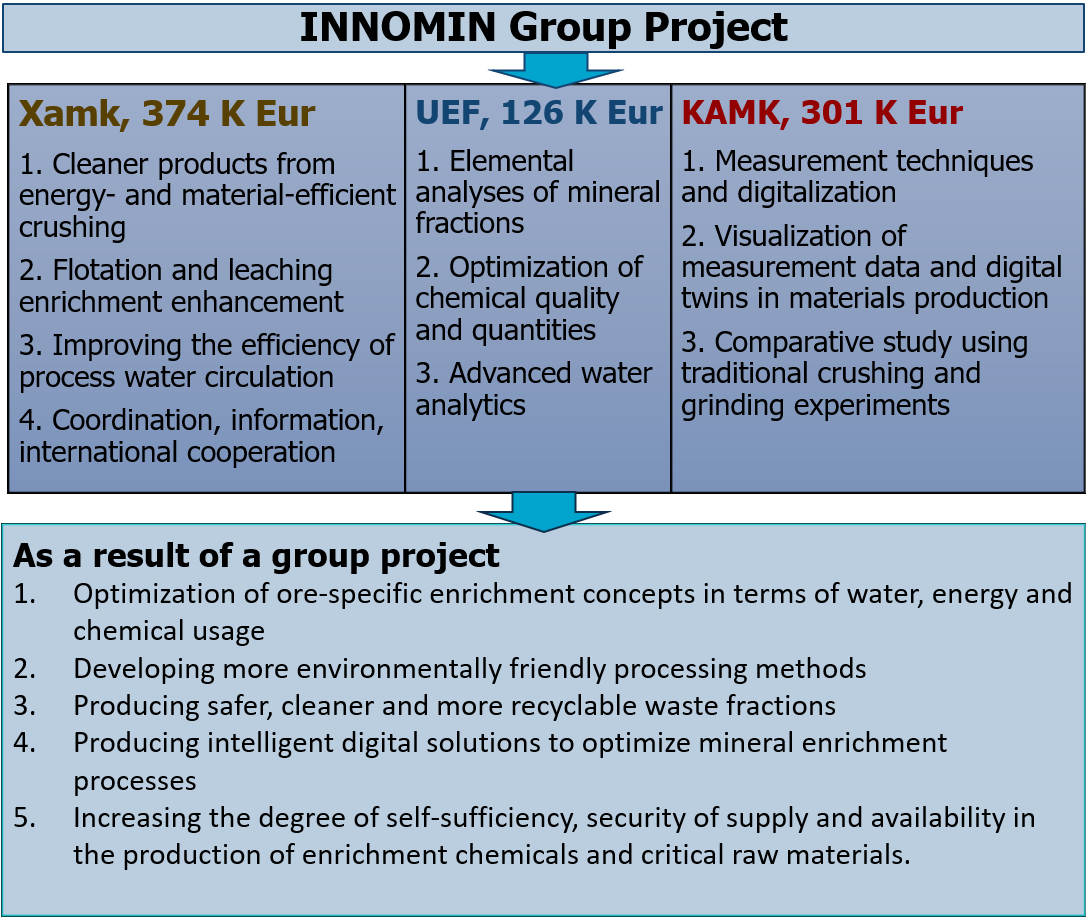

INNOMIN is a group project of three regions of Eastern and Northern Finland, where one of the main goals is to find new innovative processing solutions for manufacturing processes in the mining industry. The project strengthens innovation cooperation between RDI actors in the IP area (Xamk-UEF-KAMK).

Developing material, energy and environmentally efficient and smart technology solutions from mineral material pre-treatment to metal recovery.

Environmental efficiency in mineral processing processes

The mining and processing industry is a very important sector for Eastern and Northern Finland, as various climate technologies, such as solar panels, electric vehicles and wind turbines, are being built faster than ever before in the world. This makes the sustainable availability of critical raw materials, such as lithium, cobalt, graphite, nickel, copper, phosphorus and rare earth metals, crucial for Finland and the rest of Europe.

Many crushing, grinding and enrichment methods used in mineral processing are over 100 years old and were not originally developed on a sustainable basis. More sustainable and controlled separation methods are becoming the next cutting-edge technology of interest to the mining and process industries. These alternative technologies need to be explored to ensure an adequate and sustainable supply of critical materials, as the clean energy transition should also mean cleaner mining and mineral processing. This is due to the requirements of the clean transition to develop mineral processing methods that consume less water, energy, and chemicals.

The aim of the INNOMIN project is to find new innovative solutions for cleaner and more accurate separation and recovery methods of mineral and waste fractions needed in the green transition.

Experimental studies are carried out on ore minerals important for the Eastern and Northern Finland.

The focus of the processing solutions is on ores and minerals (such as graphite, minerals containing Co, Ni or Cu) that are critical for Eastern and Northern Finland, and their processing will be developed to be more material, energy and environmentally efficient.

One of the main goals of the project is to find new innovative processing solutions for dry enrichment, leaching and flotation enrichment of critical minerals.

Key tasks of the INNOMIN project

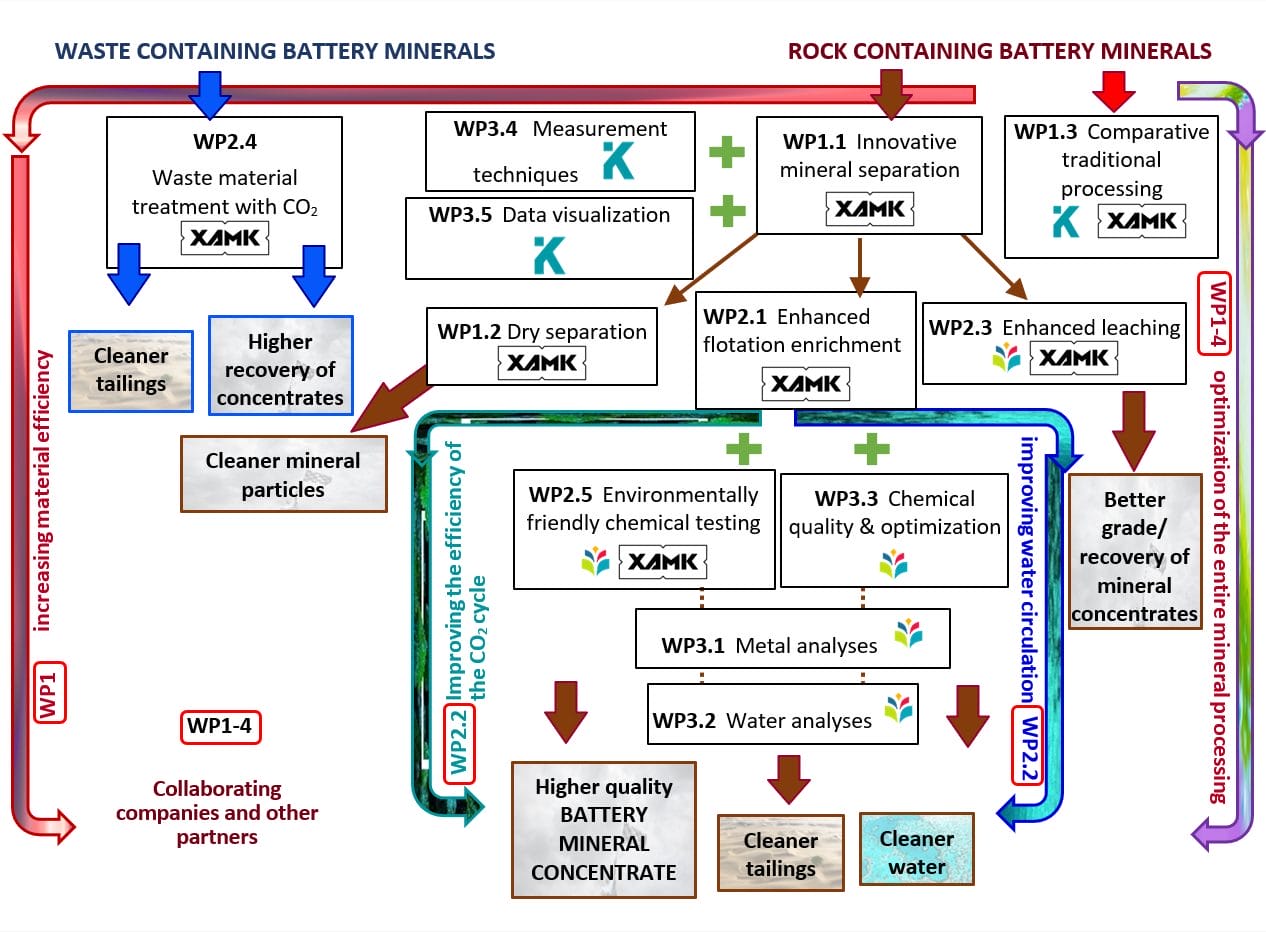

WP1. Material and energy efficient crushing

WP1.1: Separation of critical materials by continuously compressing crushing, CCC (Xamk)

WP1.2: Mineral enrichment by dry separation methods (Case Studies) (Xamk)

WP1.3: Comparative crushing and grinding research by traditional methods (KAMK) (Xamk)

WP2. Flotation and leaching enrichment for sustainable development

WP2.1: The enrichment of critical minerals under anoxic conditions (Xamk)

WP2.2: The treatment of process waters in mining concentrators (Xamk)

WP2.3: Leaching by micro-cracks (Xamk) (UEF)

WP2.4: The enrichment of useful minerals contained in mining waste (Xamk)

WP3. Analytics and smart measurement solutions

WP3.1: Metal analyses for mineral concentrates (UEF)

WP3.2: Water analyses (UEF)

WP3.3: Optimization of chemical quality and quantity (UEF)

WP3.4: Measurement techniques and digitalization (KAMK)

WP3.5: Visualization of measurement data and digital twin (KAMK)

WP4. Communication and utilization of results

WP4.1: Project coordination and management (Xamk)

WP4.2: Communication (Xamk)

WP4.3: International cooperation (Xamk)

WP4.4: Reporting (Xamk) (UEF) (KAMK)

.

.

A three-partner group project

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Mauris ex felis, facilisis neSoutheast Finland University of Applied Sciences (Xamk) is the main implementer of the project. Xamk is responsible for the coordination, management and international cooperation of the project. Xamk’s innovative process solutions for the mining industry, their design and research and testing platforms are a key part of the project’s success.

The University of Eastern Finland (UEF) is a co-implementer of the project, and the research group at UEF’s Department of Pharmacy has a significant 20 years of experience in various analytical, organic and inorganic chemistry research questions, and their expertise is crucial when studying and optimizing critical raw material flows and examining the quality and quantity of chemicals used in processes. The test environment created in the project through the cooperation between UEF and Xamk enables the optimization of chemical dosage and the testing and development of more environmentally friendly enrichment chemicals.

Kajaani University of Applied Sciences (KAMK) is the second sub-implementer of the project, and the strength of the KAMK unit is its multidisciplinary expertise in various measurement technologies and solutions for the management, analysis and utilization of measurement data. KAMK’s expertise in the project is essential and enables visual solutions for new, material-, energy- and water-efficient processing steps to be implemented during the project.

The project will create a unique network of expertise

INNOMIN produces information and develops material, energy and environmentally efficient and intelligent technology solutions for companies in the industry, from material pre-processing to material recovery.

The project create a nationally and internationally high-level knowledge network that will strengthen cooperation between the regions of Eastern and Northern Finland.

More information

Facts

INNOMIN – Environmental efficiency for mineral processing through the innovation network

Info

Budget

Project partners

Terrafame Oy

Kupukan Grafiitti Oy

Grafintec Oy

Hannukainen Mining Oy

Cleantech Projects Catalyst Oy

Savonlinnan kaupunki