CARBON BUSINESS – Towards a sustainable business with CO2 curing of concrete

PROJECT

BACKGROUND

PROCEDURE

INFO AND PERSONNEL

RESULTS

Will be updated

Project background

The built environment (buildings and infrastructure) makes up about a third of Finland’s climate emissions. Most of the carbon dioxide emissions in the built environment are caused by the consumption of energy during use, but a significant part is also formed by concrete construction and especially the use of cement in it. In the cement manufacturing 700 kilograms of CO2 per ton of clinker is released through a chemical reaction. CARBON BUSINESS – Towards a sustainable business with CO2 curing of concrete project is a continuation of the already implemented BECO – The role of concrete in a carbon neutral society and Concrete as a carbon sink – solutions for low carbon construction (BEHI) projects, in which a method has been developed to bind gaseous recycled carbon dioxide permanently to the end product while improving the concretes strength and speeding up the initial phase hardening.

CARBON BUSINESS – Towards a sustainable business with CO2 curing of concrete project continues the work of previous projects towards the industrial utilization of the results and answers the follow-up questions raised by the promising results achieved in the previous projects in the target companies. The goal of the project is to test and identify profitable carbon dioxide feeding technologies, determine the optimal binder composition and carbon dioxide binding amount, ensure the availability of recycled carbon dioxide profitably on the necessary scale, and examine the technical and economic viability of carbon dioxide curing as a whole.

Goal is to provide industry a viable product that uses CCUS carbon dioxide

The knowledge about different solutions generated in the project improves the possibility of concrete industry operators for sustainable, overall economic solutions that promote the reduction of greenhouse gases. As a long-term result, Kymenlaakso region is expected to get new business opportunities, business-oriented piloting and more impressive RDI cooperation.

The goal of CO2 curing is to utilize the captured CO2 from factories. Upscaling CO2 curing to concrete plants the industry is provided with a viable use which encourages the multiple industries to invest and move towards carbon capture technologies. Right now the most common use for recycled CO2 is to store it permanently to emptied oil fields for example in Norway. Alternative solutions for utilization of captured CO2 are relevant.

Project procedures

The goal of the project is to develop CO2 curing process of concrete comprehensively keeping in mind the profitability, achieved emission reductions, value and low-carbon effect. We will evaluate the usability of different admixtures with CO2 curing and we will define a suitable method to find out the amount of bound CO2. To achieve these goals, the project is divided to five different work packages.

In the first work package (WP1) we will examine various methods for cost-effectively introducing gaseous CO2 into the concrete during the mixing stage. The goal is to find a method that can bind CO2 into concrete not only in the largest possible amount, but also with the greatest possible efficiency. At the same time, the requirements set by different input methods are identified for the structures of concrete mills, cars, etc.

In WP1 also a method for quantification and verification of bound CO2 is studied to evaluate the preferred CO2 transfer method. Different admixtures, binders and w/c ratios will be evaluated for maximum CO2 binding. Also the effect of differing compaction amounts and methods will be studied.

Second work package (WP2) analyses and tests the composition, pore structure, durability and strength properties of carbon dioxide-containing concrete, as well as the size, location and structure of the formed CaCO3 crystals. Based on the results, the optimal amount of bound CO2 will be found, which will help to achieve the best properties of concrete (strength, durability, workability). At its best, CO2 acts as an additive, which not only creates a carbon sink in the concrete, but also reduces the amount of cement and slag used as binders, thereby further reducing the carbon footprint of concrete construction.

In the third work package (WP3) we examine the availability of CO2, identify various sidestream-based CO2 sources, map out suitable capture technologies, build collaborative networks between actors, and consider sensible delivery methods for concrete plants. The measures will create a model for how the capture and production of side stream CO2 can be used to produce low-carbon concrete that acts as a carbon store in construction.

In work package 4 (WP4) our goal is to examine the technical and economic profitability of CO2 curing and the impact of selected recipes on the low-carbon nature of concrete. In the technical and economic analyses, a whole is built around the core process, for which the analysis is carried out. The technical and economic analysis is carried out step by step for procurement and transport of CO2 to the concrete plant, the mixing of CO2 into the concrete, the effects on other necessary additives and binders, the impact of the achievable properties on the price of concrete and the value calculated for low-carbon nature.

The final work package (WP5) includes the directing of the project, reporting and communicating the results. An important aspect is also info sharing and educating of local sectors of the potential of carbon capture, CO2 curing and low carbon concrete. This website will be the main channel for the projects’ publication and communication.

Injection of CO2 and its effect for concrete properties

CARBON BUSINESS – Towards a sustainable business with CO2 curing of concrete project studies the effect of CO2 exposure to concrete when the hydration reactions are just starting (plastic phase). CO2 is added to fresh concrete in the mixing phase, which enables the benefits of CO2 mineralization to be used in the ready-mix concrete manufacturing. In the previous project the presence of additional mineralized CaCO3 was verified, and the goal in this project is to quantify it with TGA and XRD characterization methods.

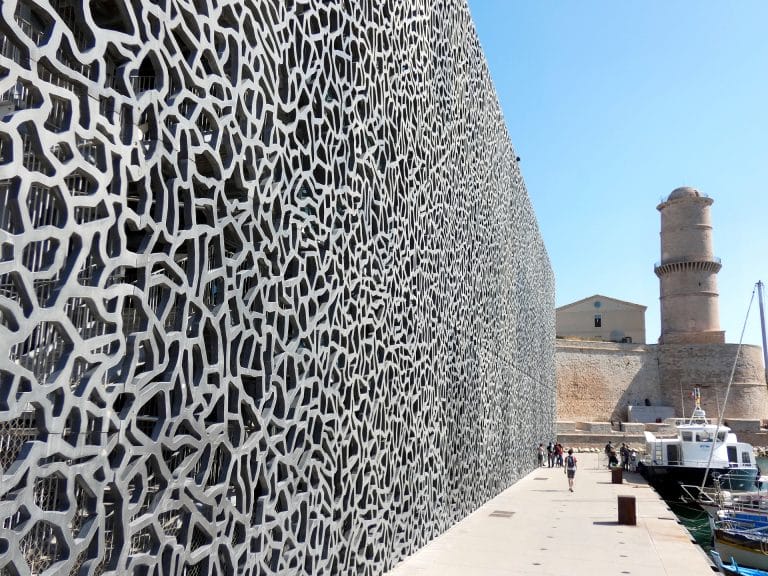

Concrete – the green material of our time?

Concrete is the most used building material – and for a good reason. Concrete material is durable, strong, long-lasting, multifunctional and economic. The disadvantage comes from the production of concretes key material, cement, since it releases a lot of CO2 emissions. So is it possible that concrete would be described a green material in the future?

Permanent carbon storing

CARBON BUSINESS – Towards a sustainable business with CO2 curing of concrete project aims also to improve the properties of concrete with CO2. The idea isn’t novel, since the subject has been studied already since the 70s. This project focuses on the implementation and applicability of the process for the ready-mix and precast concrete manufacturing.

When CO2 is introduced to concrete during mixing, it mineralizes permanently in the concrete microstructure. This makes the concrete denser and, with optimal additives and SCMs, stronger.

Bonded CO2 is away from the atmosphere and produced concrete is stronger

Project information

CARBON BUSINESS – Towards a sustainable business with CO2 curing of concrete

Info

Budget

Other:

Betonia Oy 19 500 euros

Suomen Betoniyhdistys 6 500 euros

This project is co-funded by the European Union

Other funders

.

Partners

Related articles

Matkalla kohti kestävämpää tulevaisuutta

Hiilidioksidi – hiljainen tuhoaja vai välttämätön elinehto?

Betoni – uhka ja mahdollisuus

Betonillakin on parantamisen varaa

Palonkestävää pitsiä

Askel kerrallaan kohti vihreämpää betonirakentamista

Kestävä, kestävämpi, betoni

Betoni hiilinieluna – enemmän, kuin yhden tekijän projekti

Tehokasta (W) tutkimusta

Yrityksen ja erehdyksen kautta kohti uusia epäonnistumisia

Hiilikuormasta hiilinieluksi – Betonin hiilikuormaa vähennetään hiilidioksidilla

Related projects